How might we create a faster, and more cost effective manufacturing method for nanobodies?

This project uses the production of nanobodies as a foundation to make current processes used in synthetic biology more accessible within education and undergraduate research by decreasing the expensive start-up costs.

The goal of creating these processes is for them to be replicated and improved upon. The cost of a custom nanobody can start at around $1,000/mg with machinery for protein purification and detection ranging from $2,000 to $60,000. While R1 and R2 universities are typically well funded compared to the institutions with lower Carnegie classifications, colleges at other institutional levels and intermediate/primary schools receive less, more inconsistent research funding, thus creating a need to optimize the costs of research while considering trade-offs of cheaper options.

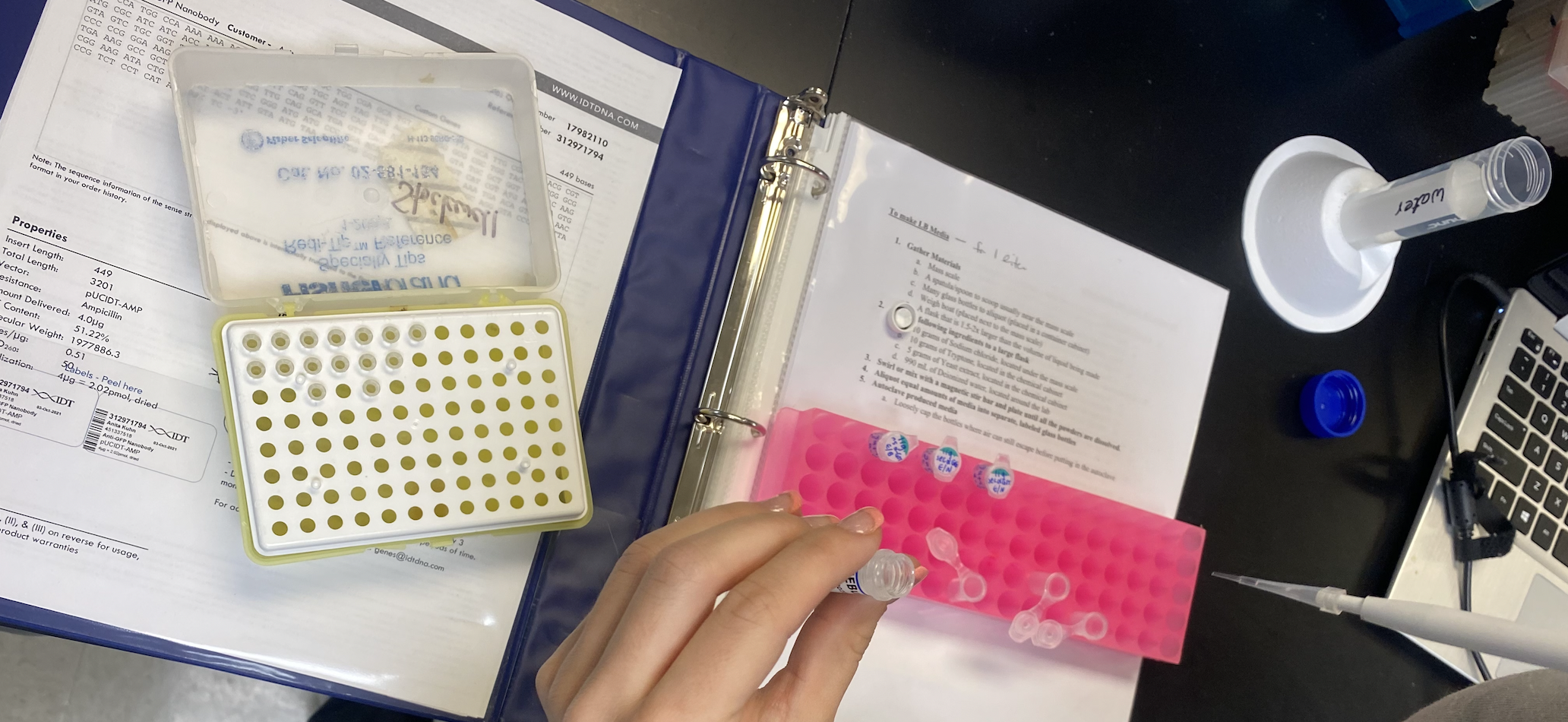

The biological build focuses on building the cell factory through biomanufacturing, which will be used to produce the nanobody protein. Current methods of producing antibodies, which are done by using a eukaryotic host, are time and cost-intensive, taking anywhere between 1 and 6 months and costing hundreds of dollars. Antibodies are also relatively large proteins and not very robust. In contrast, nanobodies can be used in place of antibodies and are easier and cheaper to produce because they use a prokaryotic host and have lower complexity but are newer so less is known about them. The team drew inspiration from the potential applications of nanobodies and identified the opportunity to genetically modify E-coli to produce these types of protein.

User Research

The goal of the produced antibody was to assist with diagnosis and therapeutics for multifactorial diseases, including cancer, diabetes, POTS, and many more. To fully understand the needs associated with this technology, the team wanted to understand the current hardships faced by these patients.

The necessity for the design was determined by understanding that for certain multifactorial diseases, the diagnosis process can take up to a decade due to the nature of them being a collection of symptoms most frequently that could indicate multiple different health outcomes. By designing a solution that allows for increased testing capacity, and lower barriers to entry, it was targeting the missing link in the medical system.

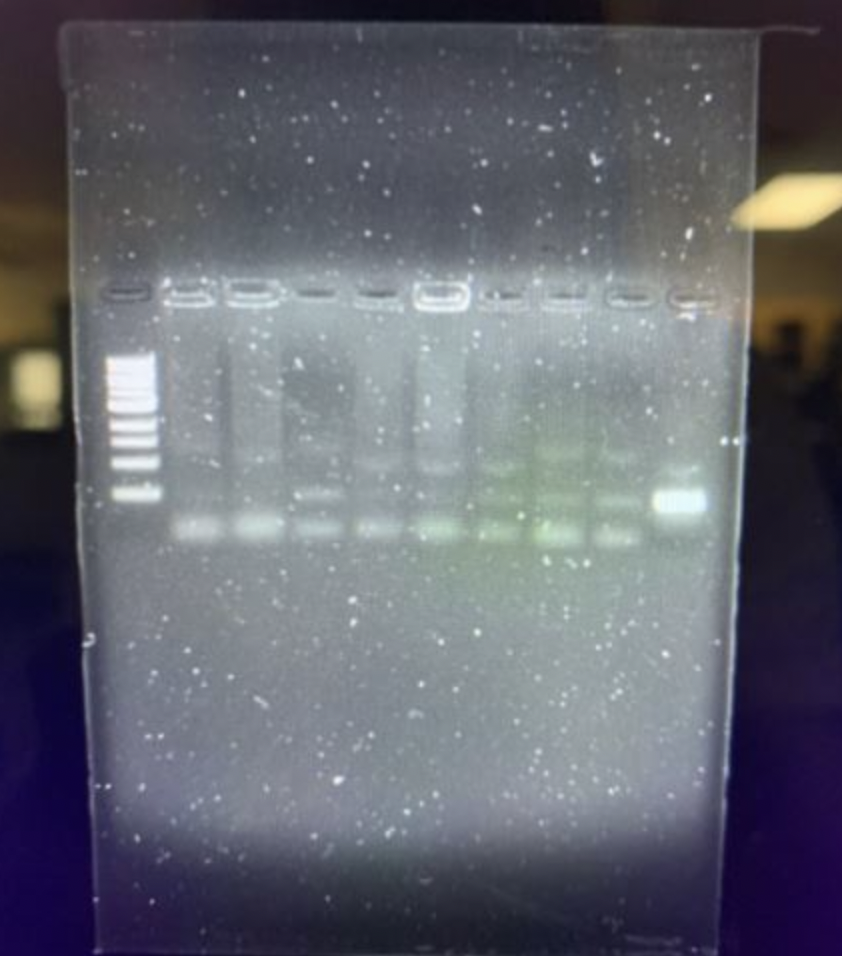

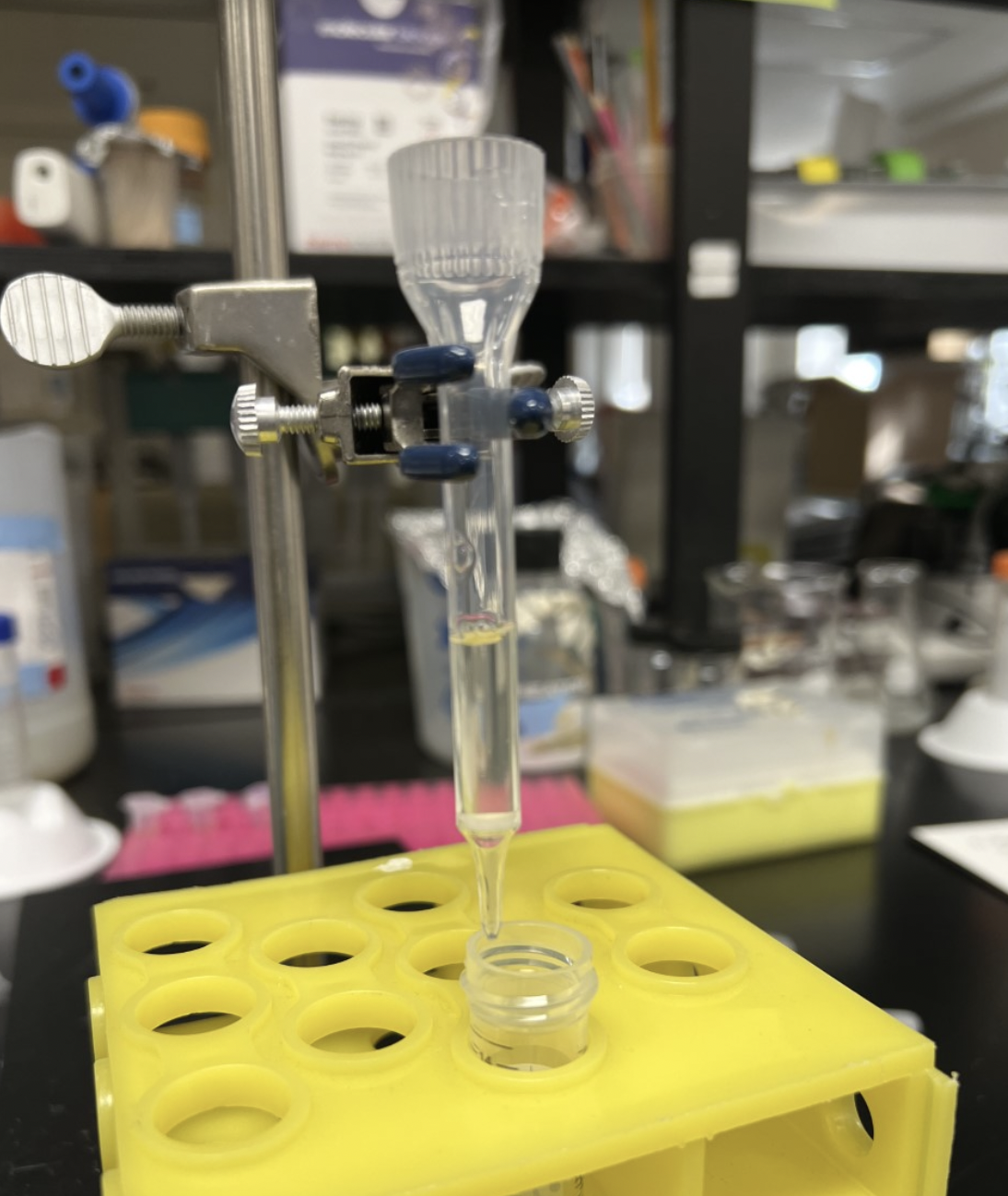

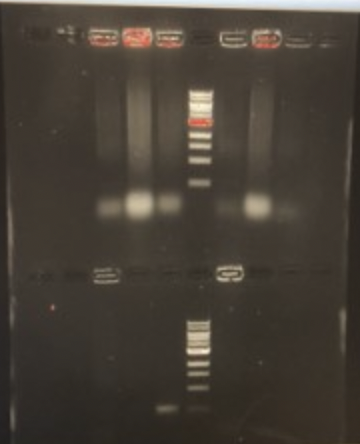

Once the biological machine is built the sample must be purified to attain a concentrated sample of nanobodies by isolating the protein from the complex mixture. There are many different methods of protein purification, but the team chose to use Bind/Elute chromatography because it can be done manually, is well-researched, and our protein is engineered to have particular his-tags. The four basic steps to this process are:

Cell lysis: cuts through the cell membrane of the bacterial host, E. coli, to extract the proteins enclosed within the cell. This step is eliminated if the cell excretes the target protein rather than producing it within its cell

Protein binding: the mixture is poured into a prepared column. The column contains agarose beads with a nickel affinity. It is rare for other molecules to be attracted to nickel which is why the team engineered the protein to have this specific affinity. The nanobodies bind to the agarose beads and the excess mixture drips off the column and gets discarded.

Washing: wash buffer, which has a salt base with a weak attraction to nickel gets added to the column next. The buffer will eliminate unbound and therefore unwanted molecules that may have stayed in the resin.

Elution: the protein of interest that is bound to the column, the elution buffer, which is a more concentrated version of the wash buffer, will be added to the column. Since the elution buffer is stronger than the wash buffer, it has a stronger affinity to nickel than the protein of interest causing the protein’s bind to the column to be broken and to drip off where it is collected in cuvettes.